Stepper Motor

INTRODUCTION

A

stepper motor (or step motor) is a brush-less, synchronous electric

motor that can divide a full rotation into a large number of steps.

The motor's position can be controlled precisely without any feedback mechanism

(see Open-loop controller), as long as the

motor is carefully sized to the application. Stepper motors are similar to switched

reluctance motors (which are very large stepping motors with a

reduced pole count, and generally are closed-loop commutated.)

FUNDAMENTALS OF OPERATION

Stepper

motors operate differently from DC brush motors, which rotate when voltage is

applied to their terminals. Stepper motors, on the other hand, effectively have

multiple "toothed" electromagnets arranged around a central

gear-shaped piece of iron. The electromagnets are energized by an external

control circuit, such as a microcontroller.

To make the motor shaft turn, first one electromagnet is given power, which

makes the gear's teeth magnetically attracted to the electromagnet's teeth.

When the gear's teeth are thus

aligned to the first electromagnet, they are slightly offset from the next

electromagnet. So when the next electromagnet is turned on and the first is

turned off, the gear rotates slightly to align with the next one, and from

there the process is repeated. Each of those slight rotations is called a

"step," with an integer number of steps making a full rotation. In

that way, the motor can be turned by a precise angle.

STEP 1

The

top electromagnet (1) is turned on, attracting the nearest tooth of a

gear-shaped iron rotor.

With

the teeth aligned to electromagnet 1, they will be slightly offset from

electromagnet 2.

STEP 2

The

top electromagnet (1) is turned off, and the right electromagnet (2) is

energized, pulling the nearest teeth slightly to the right. This results in a

rotation of 3.6° in this example.

STEP 3

The

bottom electromagnet (3) is energized; another 3.6° rotation occurs.

STEP 4

The

left electromagnet (4) is enabled, rotating again by 3.6°. When the top

electromagnet (1) is again enabled, the teeth in the sprocket will have rotated

by one tooth position; since there are 25 teeth, it will take 100 steps to make

a full rotation in this example.

Because of power requirements, induction

of the windings, and temperature management, motors cannot be powered directly

by most digital controllers. Some circuitry that can handle more power — a

motor controller such as an H-bridge — must be inserted between digital controller and

motor's windings.

The above image shows the basic

circuit of a motor controller that can also sense motor current. The circuitry

to control one winding of a motor is shown; a stepper motor would use a circuit

that could control four windings, and a normal DC motor would need circuitry to

control two windings. All of this circuitry is typically incorporated in an

integrated H-bridge

chip.

There are three

main types of stepper motors:

1. Permanent Magnet

Stepper

2. Hybrid

Synchronous Stepper

3. Variable Reluctance

Stepper

1] Permanent magnet motors use a permanent

magnet (PM) in the rotor and operate on the attraction or repulsion between the

rotor PM and the stator electromagnets.

2] Variable reluctance (VR) motors have a plain

iron rotor and operate based on the principle of that minimum reluctance occurs

with minimum gap, hence the rotor points are attracted toward the stator magnet

poles.

3] Hybrid stepper motors are named because they

use a combination of PM and VR techniques to achieve maximum power in a small

package size.

TWO PHASE STEPPER MOTOR

There

are two basic winding arrangements for the electromagnetic coils in a two phase

stepper motor: Bipolar and Unipolar.

Unipolar motors:

A

unipolar stepper motor has two windings per phase, one for each direction of

magnetic field. Since in this arrangement a magnetic pole can be reversed

without switching the direction of current, the commutation circuit can be made

very simple (e.g. a single transistor) for each winding. Typically, given a

phase, one end of each winding is made common: giving three leads per phase and

six leads for a typical two phase motor. Often, these two phase commons are

internally joined, so the motor has only five leads.

A

microcontroller

or stepper motor controller can be used to activate the drive transistors in

the right order, and this ease of operation makes unipolar motors popular with

hobbyists; they are probably the cheapest way to get precise angular movements.

Unipolar stepper motor coils

(For the experimenter, one

way to distinguish common wire from a coil-end wire is by measuring the

resistance. Resistance between common wire and coil-end wire is always half of

what it is between coil-end and coil-end wires. This is due to the fact that

there is actually twice the length of coil between the ends and only half from

center (common wire) to the end.) A quick way to determine if the stepper motor

is working is to short circuit every two pairs and try turning the shaft,

whenever a higher than normal resistance is felt, it indicates that the circuit

to the particular winding is closed and that the phase is working.

Bipolar motor:

Bipolar

motors have a single winding per phase. The current in a winding needs to be

reversed in order to reverse a magnetic pole, so the driving circuit must be

more complicated, typically with an H-bridge

arrangement. There are two leads per phase, none are common.

Static

friction effects using an H-bridge have been observed with certain drive

topologies. Because windings are better utilized, they are more powerful than a

unipolar motor of the same weight.

8-lead stepper:

An

8 lead stepper is wound like a unipolar stepper, but the leads are not joined

to common internally to the motor. This kind of motor can be wired in several

configurations:

- Unipolar.

- Bipolar

with series windings. This gives higher inductance but lower current per

winding.

- Bipolar

with parallel windings. This requires higher current but can perform

better as the winding inductance is reduced.

- Bipolar with a single winding per phase. This method will run the motor on only half the available windings, which will reduce the available low speed torque but require less current.

Higher-phase count stepper motors

Multi-phase stepper motors with

many phases tend to have much lower levels of vibration, although the cost of

manufacture is higher.

Stepper motor drive circuits

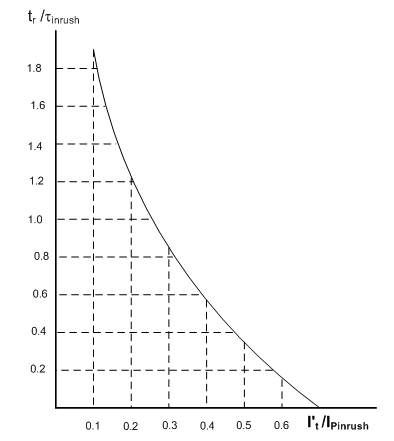

Stepper motor performance is

strongly dependent on the drive circuit. Torque curves may be extended to

greater speeds if the stator poles can be reversed more quickly, the limiting

factor being the winding inductance. To overcome the inductance and switch the

windings quickly, one must increase the drive voltage. This leads further to

the necessity of limiting the current that these high voltages may otherwise

induce.

L/R drives circuits:

L/R drive circuits are also

referred to as constant voltage drives because a constant positive or negative

voltage is applied to each winding to set the step positions. However, it is

winding current, not voltage that applies torque to the stepper motor shaft.

The current I in each winding is related to the applied voltage V by the

winding inductance L and the winding resistance R. The resistance R determines

the maximum current according to Ohm's law

I=U/R. The inductance L determines the maximum rate of change of the current in

the winding according to the formula for an Inductor

dI /dt = U/L. Thus when controlled by an L/R drive, the maximum speed of a

stepper motor is limited by its inductance since at some speed, the voltage U

will be changing faster than the current I can keep up.

With

an L/R drive it is possible to control a low voltage resistive motor with a

higher voltage drive simply by adding an external resistor in series with each

winding. This will waste power in the resistors, and generate heat. It is

therefore considered a low performing option, albeit simple and cheap.

Chopper drive circuits:

Chopper drive circuits are also

referred to as constant current drives because they generate a somewhat

constant current in each winding rather than applying a constant voltage. On

each new step, a very high voltage is applied to the winding initially. This

causes the current in the winding to rise quickly since dI/dt = V/L where V is

very large. The current in each winding is monitored by the controller, usually

by measuring the voltage across a small sense resistor in series with each

winding.

When the current exceeds a

specified current limit, the voltage is turned off or "chopped",

typically using power transistors. When the winding current drops below the

specified limit, the voltage is turned on again. In this way, the current is

held relatively constant for a particular step position. This requires

additional electronics to sense winding currents, and control the switching,

but it allows stepper motors to be driven with higher torque at higher speeds

than L/R drives. Integrated electronics for this purpose are widely available.

Phase current waveforms

A stepper motor is a polyphase AC synchronous motor (see Theory below), and it

is ideally driven by sinusoidal current. A full step waveform is a gross

approximation of a sinusoid, and is the reason why the motor exhibits so much

vibration. Various drive techniques have been developed to better approximate a

sinusoidal drive waveform: these are half stepping and micro stepping.

Full step drive (two phases on)

This

is the usual method for full step driving the motor. Both phases are always on.

The motor will have full rated torque.

Wave drive:

In

this drive method only a single phase is activated at a time. It has the same

number of steps as the full step drive, but the motor will have significantly

less than rated torque. It is rarely used.

Half stepping:

When

half stepping, the drive alternates between two phases on and a single phase

on. This increases the angular resolution, but the motor also has less torque

at the half step position (where only a single phase is on). This may be

mitigated by increasing the current in the active winding to compensate. The

advantage of half stepping is that the drive electronics need not change to

support it.

Microstepping:

What is commonly referred to as

micro stepping is actual "sine cosine micro stepping" in which the

winding current approximates a sinusoidal AC waveform. Sine cosine micro

stepping is the most common form, but other waveforms are used.

Regardless of the waveform used, as the micro steps become smaller, motor

operation becomes more smooth, thereby greatly reducing resonance in any parts

the motor may be connected to, as well as the motor itself. It should be noted

that while micro stepping appears to make running at very high resolution

possible, this resolution is rarely achievable in practice regardless of the

controller, due to mechanical stiction and other sources of error between the specified and actual

positions. In professional equipment gear heads are the preferred way to

increase angular resolution.

Step size repeatability is an

important step motor feature and a fundamental reason for their use in

positioning. Example: many modern hybrid step motors are rated such that the

travel of every Full step (example 1.8 Degrees per Full step or 200 Full steps

per revolution) will be within 3% or 5% of the travel of every other Full step;

as long as the motor is operated within its specified operating ranges. At

large step size reductions it is possible to issue many micro step commands

before any motion occurs at all and then the motion can be a "jump"

to a new position.

Theory

A step motor can be viewed as a

synchronous AC motor with the number of poles (on both rotor and stator)

increased, taking care that they have no common denominator. Additionally, soft

magnetic material with many teeth on the rotor and stator cheaply multiplies

the number of poles (reluctance motor). Modern steppers are of hybrid design,

having both permanent magnets and soft iron cores.

To achieve full rated torque, the coils in a

stepper motor must reach their full rated current during each step. Winding

inductance and reverse EMF generated by a moving rotor tend to resist changes

in drive current, so that as the motor speeds up, less and less time is spent

at full current — thus reducing motor torque. As speeds further increase, the

current will not reach the rated value, and eventually the motor will cease to

produce torque.

Pull-in

torque:

This is the measure of the torque produced by a stepper motor when it is

operated without an acceleration state. At low speeds the stepper motor can synchronies

itself with an applied step frequency, and this pull-in torque must overcome

friction and inertia.

Pull-out torque:

The

stepper motor pull-out torque is measured by accelerating the motor to the

desired speed and then increasing the torque loading until the motor stalls or

"pulls out of synchronism" with the step frequency. This measurement

is taken across a wide range of speeds and the results are used to generate the

stepper motor's dynamic performance curve. As noted below this curve is

affected by drive voltage, drive current and current switching techniques. It

is normally recommended to use a safety factor of between 50% and 100% when

comparing your desired torque output to the published pull-out torque

performance curve of a step motor.

Detent torque:

Synchronous

electric motors using permanent magnets have a remnant position holding torque

(called detent torque, and sometimes included in the specifications) when not

driven electrically. Soft iron reluctance cores do not exhibit this behavior.

Stepper motor characteristics

1. Stepper motors

are constant power devices.

2. As motor speed

increases, torque decreases.

3. The torque curve

may be extended by using current limiting drivers and increasing the driving

voltage.

4. Steppers exhibit

more vibration than other motor types, as the discrete step tends to snap the

rotor from one position to another.

5. This vibration

can become very bad at some speeds and can cause the motor to lose torque.

6. The effect can

be mitigated by accelerating quickly through the problem speeds range,

physically damping the system, or using a micro-stepping driver.

7. Motors with a

greater number of phases also exhibit smoother operation than those with fewer

phases.

Stepper motor ratings and specifications

Stepper motors nameplates

typically give only the winding current and occasionally the voltage and

winding resistance. The rated voltage will produce the rated winding current at DC: but this

is mostly a meaningless rating, as all modern drivers are current limiting and

the drive voltages greatly exceed the motor rated voltage.

A stepper's low speed torque

will vary directly with current. How quickly the torque falls off at faster

speeds depends on the winding inductance and the drive circuitry it is attached

to, especially the driving voltage.

Steppers should be sized

according to published torque curve, which is specified by the manufacturer at

particular drive voltages and/or using their own drive circuitry. It is not

guaranteed that you will achieve the same performance given different drive

circuitry, so the pair should be chosen with great care.

Comments

Post a Comment